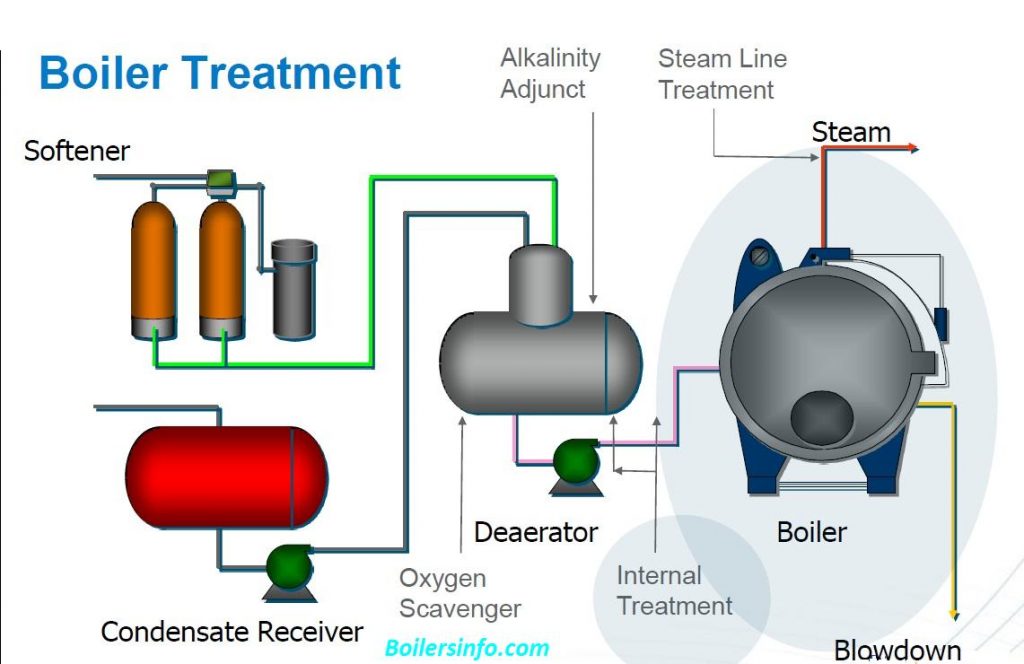

Boiler water treatment is necessary to producing quality steam on demand depends on properly managed water treatment to control steam purity deposits and corrosion there are two main types of boiler feed water treatment internal boiler water treatment method and external boiler water treatment a boiler is the sump of the boiler system.

Boiler feed water treatment process pdf.

The most appropriate boiler feed water treatment system will help the facility avoid costly plant downtime expensive maintenance fees and boiler failure as a result of scaling corrosion and fouling of the.

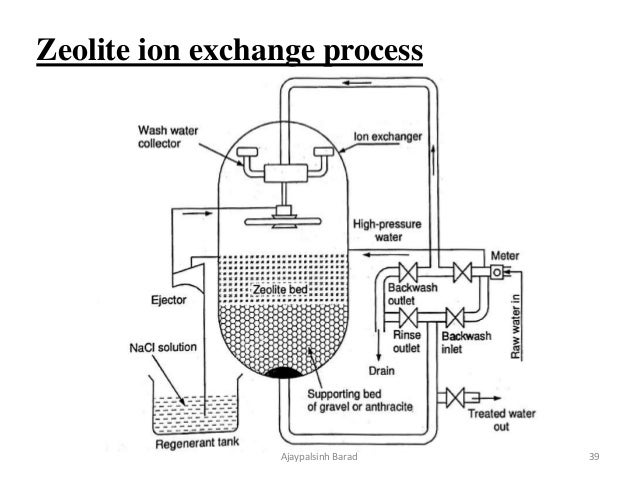

A raw water is treated before it is fed into the boiler.

There are two designs that typically are used a spray type and a tray type de aerator figure 2 which for the purposes of this discussion provide essentially the same end result.

A de aerator is used for virtually every boiler application at some stage during the feedwater treatment process.

While the elimination of oxygen from boiler feed water is the major step in controlling boiler corrosion corrosion can still occur.

These pre boiler system components include the integrated or supplementary water pre treatment equipment used to process the boiler makeup.

Internal treatment compliments external treatment and is required regardless of whether the impurities entering the boiler with the feedwater are large or small in quantity.

The goal is to improve the quality of water before it is used as boiler feed water.

Internal treatment of boiler feedwater.

This is known as external treatment.

For industrial companies using a boiler for its facility some type of boiler feed water treatment system is usually necessary to ensure an efficient process and quality steam generation.

A treatment for boiler feed water may be divided into two broad classifications external and internal treatment.

Boiler water treatment introduction a boiler is a closed vessel in which water under pressure is transformed into steam by the application of heat.

In the boiler furnace the chemical energy in the fuel is converted into heat and it is the function of the boiler to transfer this heat to the contained water in the most efficient manner.

Some feed water treatment chemicals such as chelants if not properly applied can corrode feed water piping control valves and even the boiler internals.

It ultimately receives all of the pre boiler contaminants.

The pre boiler section of a steam boiler encompasses the boiler system s structural components that hold move and treat the water before the water enters the boiler.